Automatic L-Bar-Sealer (up to 40 cycles/min)

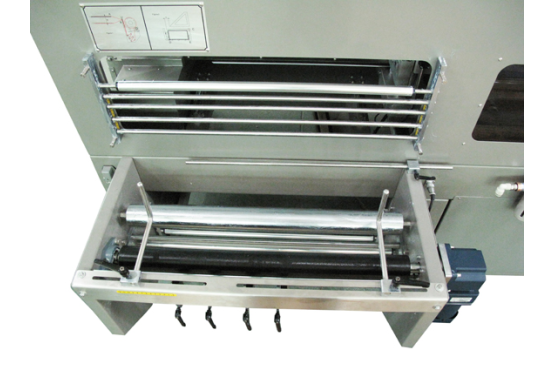

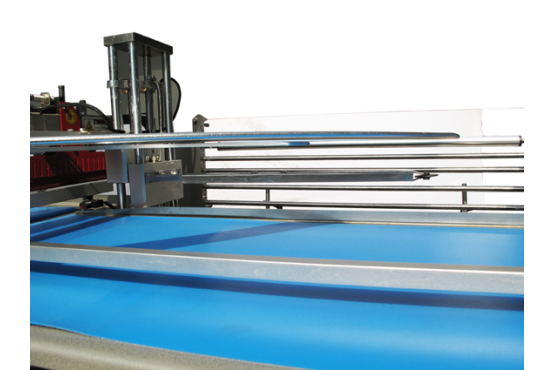

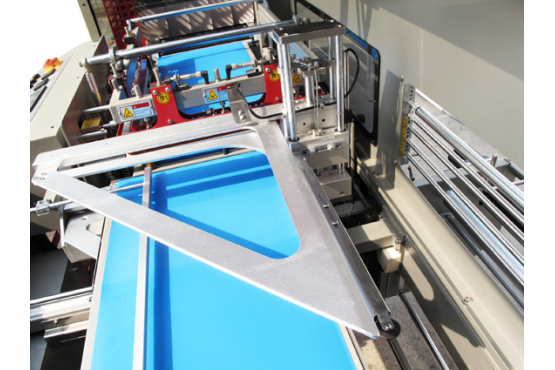

The automatic L-bar-sealer is the ideal entry-level solution for long-term and automatic packaging processes. This sensor-controlled packaging line of film sealing machines can be fed manually or all-automatically. The film sealing machine reliably guarantees stable side seams for all films. The film is separated by two permanently heated Teflon knifes (L-angle). During this process, the center folded film is sealed by adjustable heat isolation. The use of our vertical pillow bag machine enables the user to pack different product sizes depending on the respective sealing frame size. The fast conversion to other product sizes guarantees an efficient and cost-effictive workflow. The shrinking process (shrink film packaging) is optimally prepared, thanks to its integrated product centering unit (centered sealing seam of the products).

Technical Details

- simple handling due to the digital program selection of 10 individually storable programs

- electrical height adjustment of the sealing stamp (product centering)

- discrete temperature control for the sealing knifes (lengthwise/crosswise)

- bundlings of one ore more products possible

- electronically adjustable conveyor belt speed

- integrated batch counter

- combinable with a shrink tunnel

- protective cover (sensor-controlled)

- automatic winding of film waste

Additional Options:

- film fold device

- labelling-/ printing unit

- stainless steel construction

- product supply unit / product pusher / kissing belt function

Automatic L-Bar-Sealer: Product Video

Packaging of face masks

Packaging of face masks

L-Bar Sealer and Shrink Tunnel - Shrinking of Paper Towels

L-Bar Sealer and Shrink Tunnel - Shrinking of Chicken

L-Bar Sealer and Shrink Tunnel - Shrinking of Gingerbread

L-Bar Sealer and Shrink Tunnel - Shrinking of Brokkoli

Different Models:

* L-Sealing Stamp: permanently heated L-shaped and Teflon-coated film sealing knife (facilitates thin and neat seams)

** It is not possible to combine all maximum dimensions

*** The output quantities per minute are averages depending on film type, thickness, product dimension and machine handling.