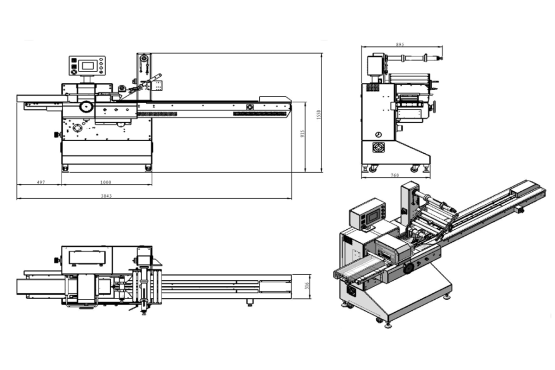

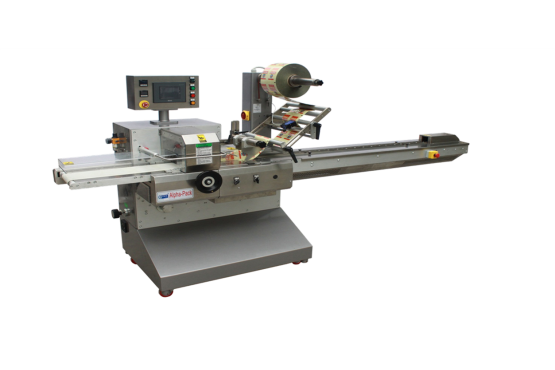

Horizontal Pillow Bag Machine

Film feeding from the top

Our horizontally working DEAHP-line pillow bag machines, also known as flow-packing machines, are a fast and all-automatic solution for the packing of different products in polypropylene, polyolefin, cellophane and laminating films. The closing of the film happens longitudinally and transversely by extremely stable sealing seams. During this process, the film is merged from below and above. The automatic pillow bag machine processes transparent and printed films and is individually adapted to the product. The product is fed manually or automatically via a transport chain.

Application examples: Medical and pharmaceutic industry, fruits and vegetables, technical products, pastries and frozen food

Technical Details

- steel frame or stainless steel construction

- product transport via gripper loading

- Teflon-coated sealing stamps, permanently heated

- simple touch screen operation via color symbols

- continuous product feed due to photocell control

- safety protection covers / emergency signal lamp

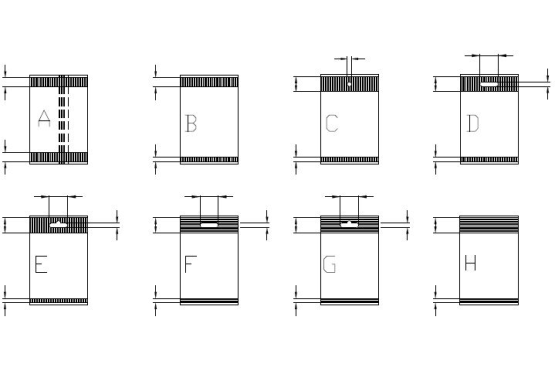

- 3-sideed seal seam packaging (fin seal)

- longitudinal sealing at the bottom of the bag

- rotating transverse sealing system

- combinable with our shrink tunnels

- customized modifications / designs upon request

Video recordings of our horizontal pillow bag machines in operation

Pillow Bag Machine (horizontal): Packaging of face masks

DEAHP-500-3S: Sandwiches

Different Models:

* It is not possible to combine all maximum dimensions

** The output quantities per minute are averages depending on film type, thickness, product dimension and machine handling

Additional Options:

- Box-Motion for high-speed quantities

- thermal transfer printing (best-before dates)

- stainless steel design for the food secotor(IP 65)

- cooling applications for ice-cream packagings

- zig-zag-knifes, euro standard punches etc.

- automatic stop when there is no product (no product = no bag)

- application with shrink films (flow shrink)

- film guidance from below for light products (e.g. herbs, greeting cards)

- gas-injection units for a protective atmosphere (product shelf life extension)

- automatic product feed systems, slide-in systems (in cycles)

- perforation units for an easy opening (pull strip)

- length-independent product processing due to photocell scanning

Optional Accessories:

- photocell

- printer (e.g. for best-before dates)

- stainless steel construction

- transmission for automatic feeder

Our recommendations to this machine: